The Brandenburger GL-M material has been developed for applications with high continuous operating temperature. Primary components are high-quality mica fractions combined with silicon-resin impregnation.The insulating materials, pressed to produce laminates, are non-flammable.

Special material characteristics:

- High Long-Term Temperature Resistance

- Good Insulation Properties

- Good Compressive Strength

- Coefficient of Expansion Similar to that of Steel

Areas of application:

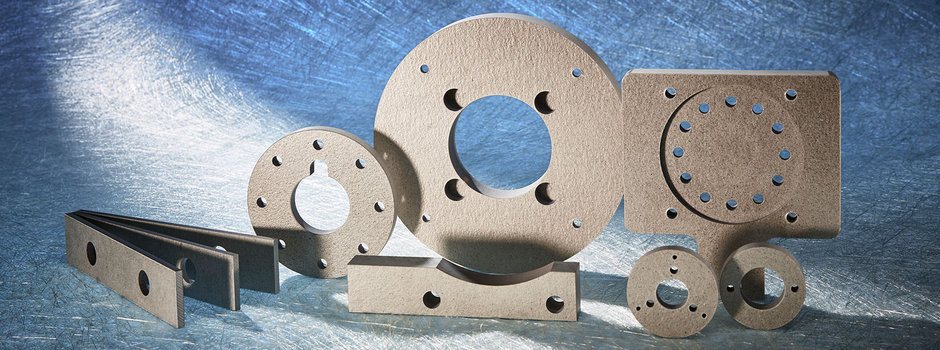

GL-M is mainly used as permanently fixed, all-over heat protection in soldering systems, high-temperature presses and blanking devices. This material is also ideal for induction and electric arc furnaces, as well as switch cabinet and apparatus engineering because it is electrically non-conductive.

Thanks to its excellent properties, this material is suitable for many insulation types; e.g. in

glass processing, in welding systems, in pot soldering machines, or for extrusion dies in

plastics processing.

| Thermal | ||

|---|---|---|

| Temperature resistance (short-term) | 600 ℃ | 1112 ℉ |

| Temperature resistance (long-term) | 400 ℃ | 752 ℉ |

| Thermal conductivity | 0.3 W/mK | 0.17 btu/ft h ℉ |

| Coefficient of the linear expansion | 10•10-6 | 10•10-6 |

| Mechanical | ||

| Compressive strength (room temperature) | 400 N/mm2 | 58015.1 psi |

| Flexual strength | 200 N/mm2 | 29007.5 psi |

| Compressive strength (200 ℃) | 250 N/mm2 | 36259.4 psi |